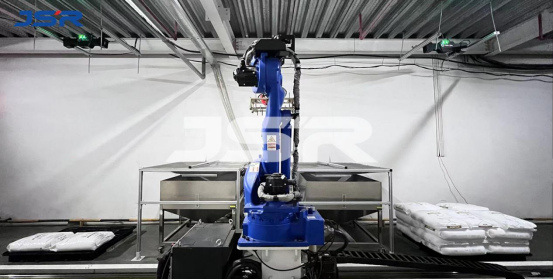

JSR's robotic pertractatio processus automation cum YASKAWA tractatio robot applicata est in saccis tractandis et inpacatio particulae plasticae; et a *ccurate, certa et sustineri operatio pertractatio, valorem afferens ad productionem automationem promovendam.

Nulla in re aspectus machinationis, agriculturae, vestitionis, constructionis vel cotidianae vitae, figuram particulae plasticae REDIVIVUS videre possumus. Post packaging, hae particulae manually tractandae sunt, quae labor intermissus est magno sumptu et magno labore intensio. Antea operandi tempus emptoris erat 8 horarum, et quisque sacculus materiarum 25Kg erat. Facultas manualis est 2 sacci per minutias, et nonaginta sacci in die disiungi possunt. Tempus operantes cum robot pertractatio et disgregatio est 24 horarum, quae continue operari potest, et efficientia 3 saccorum per minutias, et 4320 sacci in die disiungi possunt.

Solutiones perficiuntur per Jieshlat pro clientibus: Yaskawa tractatio robot GP180, 7.5m terra longa rail, materia bin, materia eculeo, GP180 maximum onus 180kg, bracchium maximum 2702mm. 7.5m orbitae terrae iter efficax est 6m, celeritas movens 0.7m/s. 3D visualis identificatio ratio vacua. 3D identificatio visivae blanking systema, camera cum doctrina functionis, per primam materiam datam acquisitionem et postea materialem exemplar, ut successus rate agnitionis camerae 99,9% est.

Productio automatica valde melioratur efficientiam laboris, capacitatem productionis stabilis, accuratam traditionem, altam securitatem, rationabilem usum areae exsistentis, corporis imaginem et officinam munditiam meliorem, ad productionem inanibus consequendam.

Post tempus: Sep-26-2022